The choice between pure battery, hydrogen, methanol and ammonia as energy storage solutions can sometimes appear to be an impossible choice with competing claims. At Ecomar Propulsion, we deal with these questions every day.

The fact is all the new fuels have one ambition: Maximum energy in the smallest space possible. This “energy density” is the start of the process to determine which fuel is best for you. Regardless of which one you prefer; they all use hydrogen.

At Ecomar Propulsion, we have come to the conclusion that for the next decade or longer, the only viable energy carrier for inshore vessels below 300GWT is hydrogen. Mid-sized vessels 250 – 500GWT have a choice to make between hydrogen and methanol and larger vessels will undoubtedly need to select between Methanol and Ammonia.

As a result of our groundbreaking work, we have created a simple series of questions to help our clients decide what is best for their vessels.

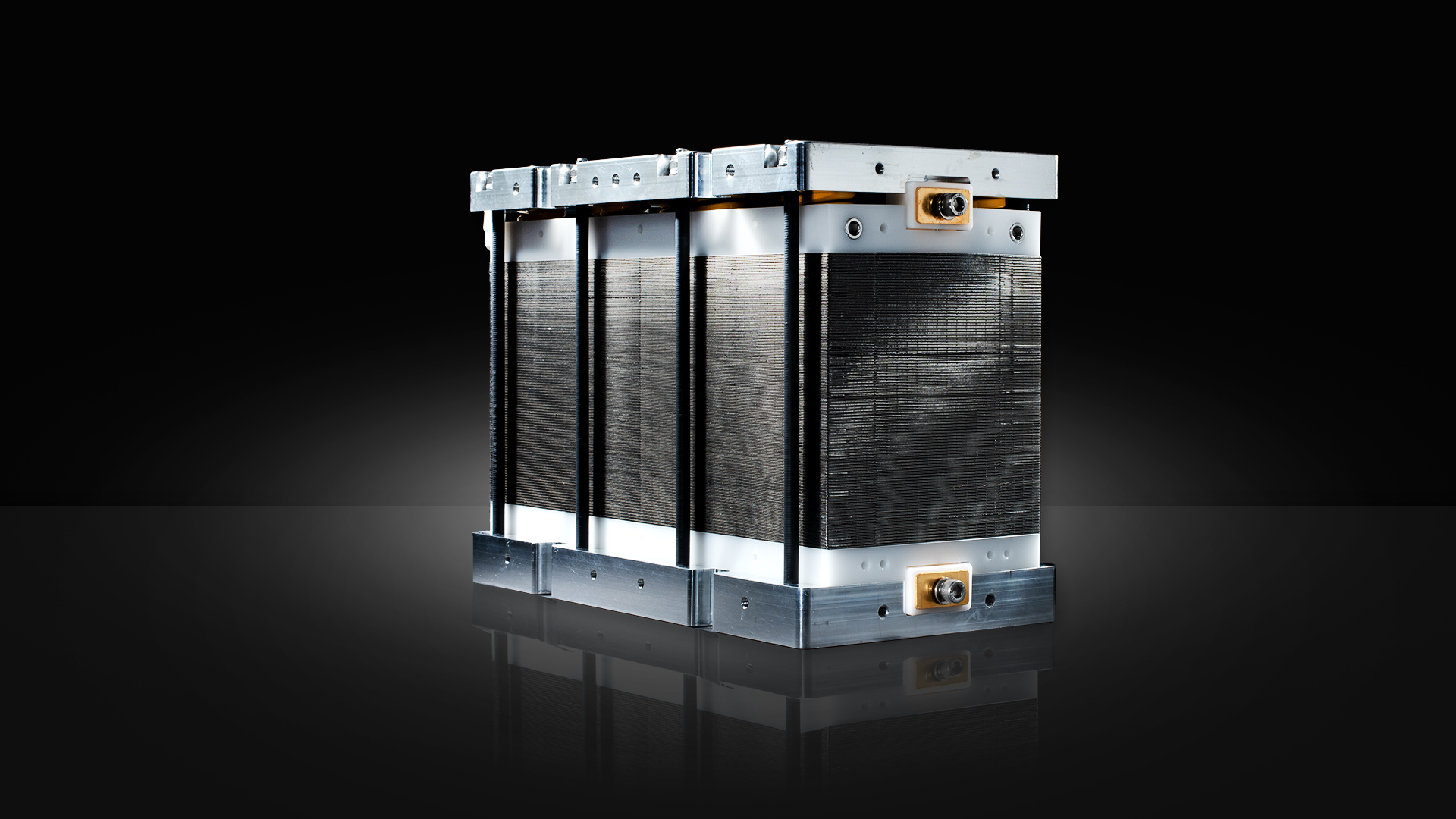

You can install hydrogen in individual high-pressure tanks or via specialised containerised storage that meets IMO and national standards. The fuel is used in fuel cells to drive ship machinery.

It is possible to inject hydrogen into conventional motors fuels but it there are serious problems associated with that approach and we never recommend this option.

In all other ways yes. Hydrogen can be used to provide power to all ship systems.

Basically, this is a fantasy that only works on spacecraft. Hydrogen is used to generate electricity through fuel cells. This electrical power is then used to drive electric propulsion.

Zero emissions. Fast fuelling. Easy to retrofit. Probably reducing fuel costs as adoption increases. No need to connect to energy grids or for massive infrastructure investment.

Hydrogen is becoming the fuel of choice for many industries. For ports it is a relatively low cost way to decarbonise. Installing an electrolyser and converting machinery to hydrogen is a viable way to rapidly decarbonise. As take off from production increases, costs reduce and investments become profitable in a very short period.

The availability of hydrogen makes it a viable option for all inland commercial vessels and most offshore vessels up to 300DWT except for high performance craft. For larger vessels, hydrogen is a realistic and cost-effective solution. This applies particularly for ferries and coastal craft. Larger vessels will benefit from range extension and near total removal of GHG emissions whilst cold ironing.

In port operations, inland waterways and point to point operators are ideally suited to commissioning a 100% hydrogen fuelled boat.

Traditional diesel bunkering can be replaced by hydrogen bunkering where ports have installed an electrolyser or where road delivery is feasible. Hydrogen bunkers contain high pressure gas that is ready to be transferred by pipelines or by swapping containers when the vessel is at quayside.

Fuel cells are best when they operate at 100% output. Therefore, a battery is used to “buffer” the demand from the motors with the fuel cells. This adds to reliability and reduces service costs. It also increases the lifespan of the fuel cell.